Pipeline Welding Inspection: Ensuring Conformity with Market Criteria

Pipeline Welding Inspection: Ensuring Conformity with Market Criteria

Blog Article

Advanced Strategies in Pipe Welding Assessment: Advancements and Technologies for Enhanced Accuracy and Reliability in Weld Evaluation

The landscape of pipe welding assessment is going through a substantial improvement, driven by innovative methods that promise to enhance both precision and dependability in weld assessments. Technologies such as automatic inspection systems and advanced imaging innovations are redefining conventional techniques, while non-destructive testing methods ensure product integrity is maintained. As these technologies advance, they not only raise defect detection prices however additionally enable a lot more reliable upkeep approaches. However, the effects of these developments extend beyond immediate advantages, raising vital concerns about future techniques and standards in the sector.

Significance of Weld Inspection

Ensuring the integrity of pipeline welds is crucial to the overall security and dependability of industrial systems. Strenuous inspection of welds is indispensable to the lifecycle of pipe framework.

The relevance of weld inspection extends beyond mere conformity with governing requirements. It works as a positive procedure to determine and remedy flaws, such as incomplete combination, porosity, or cracks, before they rise right into severe problems. Effective assessment methods also add to the durability of pipelines, minimizing maintenance costs and boosting operational efficiency.

In addition, thorough weld inspections foster depend on amongst stakeholders, consisting of governing bodies, financiers, and the neighborhoods offered by these pipelines. By ensuring that all welds fulfill the needed criteria, companies can mitigate threats and maintain their track records. In recap, weld inspection is important not just for functional integrity however additionally for the more comprehensive effects it holds for safety and security and environmental stewardship.

Automated Examination Solutions

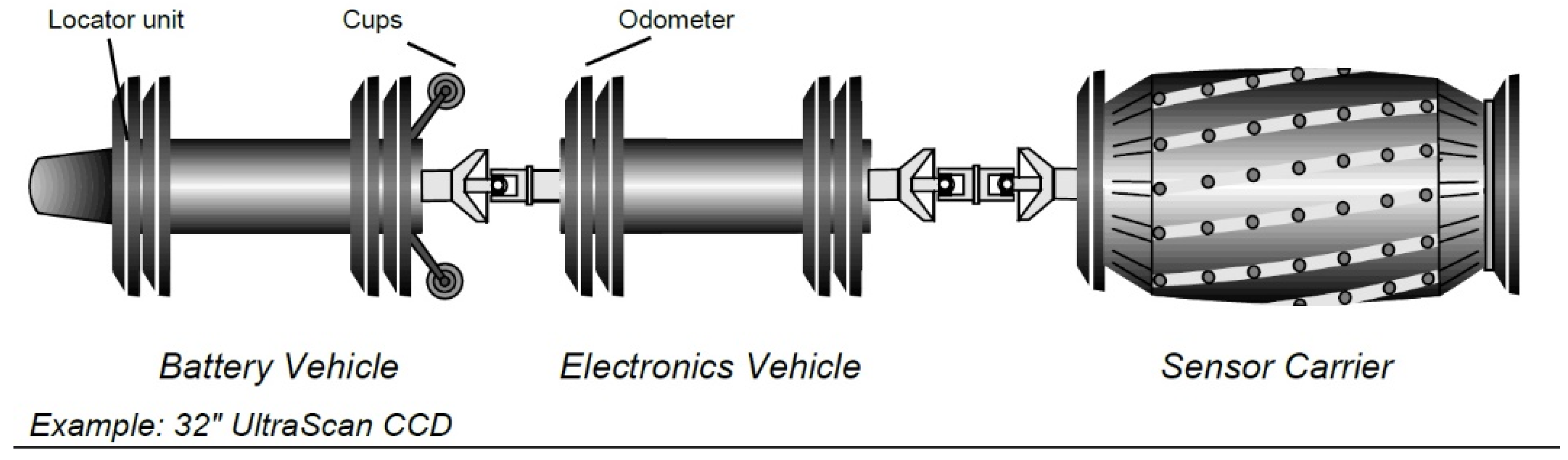

The combination of computerized inspection systems in pipe welding has actually changed the method to ensuring weld quality and stability. These systems employ advanced robotics and expert system to perform inspections that are not just faster but likewise extra constant than standard methods. Automated systems can cover substantial lengths of pipelines successfully, recording information that human examiners might ignore because of tiredness or ecological problems.

One of the essential advantages of computerized examination systems is their capacity to operate in harmful environments, minimizing the danger to human assessors. They make use of various non-destructive testing (NDT) strategies, such as ultrasonic testing and magnetic particle assessment, to evaluate weld stability without compromising the structure. The data gathered is processed in real-time, enabling for instant feedback and timely corrective actions when problems are determined.

Furthermore, automated systems help with the standardization of inspection procedures, ensuring that each weld is examined versus constant standards. This not only improves the integrity of outcomes yet likewise simplifies compliance with governing standards. As markets remain to prioritize safety and functional effectiveness, the function of automatic examination systems in pipe welding will most certainly broaden, leading the way for a lot more innovative quality control techniques.

Advanced Imaging Technologies

Often utilized in modern pipeline welding assessments, advanced imaging modern technologies have dramatically improved the capability to find and assess weld problems. Methods such as digital radiography, computed tomography, and thermographic imaging provide inspectors with high-resolution pictures that expose sub-surface flaws and architectural incongruities that may be undetectable to the naked eye.

Digital radiography makes use of digital sensors to catch photos, permitting prompt testimonial and enhanced image comparison. This results in much faster assessments and boosted accuracy in determining important flaws. Calculated tomography, on the other hand, uses three-dimensional imaging, allowing inspectors to envision intricate geometries and evaluate the stability of welds look here from several angles - Pipeline Welding Inspection. This deepness of analysis is very useful for spotting problems that conventional methods may ignore.

Thermographic imaging uses infrared modern technology to discover variants in temperature, identifying areas of prospective weak point or tension within the weld. These advanced imaging technologies not only boost flaw discovery rates but also decrease the moment and sources required for pipeline inspections. Therefore, they play an important duty in preserving pipeline safety and reliability, making sure compliance with market standards while lessening operational dangers.

Non-Destructive Checking Techniques

Making use of numerous strategies, non-destructive testing (NDT) methods are vital in pipeline welding examinations, permitting the assessment of weld stability without jeopardizing the product's architectural integrity. NDT encompasses a variety of methods, consisting of ultrasonic screening (UT), radiographic screening (RT), magnetic particle screening (MT), and dye penetrant screening (PT) Each approach has unique advantages and applications relying on the particular requirements of the evaluation.

Ultrasonic screening utilizes high-frequency sound waves to discover inner problems, offering accurate dimensions of weld thickness and integrity. Pipeline Welding Inspection. Radiographic screening employs X-rays or gamma rays to produce pictures of the weld, revealing internal flaws that might not show up on the surface. Magnetic particle screening is reliable for spotting surface and near-surface gaps in ferromagnetic materials, while dye penetrant screening highlights surface area splits by utilizing a tinted color

Integrating these NDT approaches into pipe welding assessments enhances the accuracy and dependability of weld analyses, making sure that potential failures are recognized early. As sectors require greater requirements for safety and efficiency, the role of NDT in preserving the stability of bonded frameworks proceeds to be essential in pipeline construction and maintenance.

Future Patterns in Weld Analysis

As we seek to the future of weld assessment, advancements in modern technology are positioned to transform the techniques used for reviewing pipeline honesty. The integration of synthetic intelligence (AI) and artificial intelligence in assessment procedures is anticipated to improve the precision of flaw detection and predictive upkeep. These modern technologies permit for real-time information analysis, enabling examiners to identify potential concerns prior to they escalate into significant issues.

Additionally, making use of drones equipped with sophisticated imaging systems is gaining traction. These airborne assessments can cover huge areas swiftly, capturing high-resolution pictures and data that can be evaluated for defects in hard-to-reach locations. This not only enhances safety and security but likewise increases efficiency published here in the examination process.

Furthermore, the advancement of wise sensors installed in pipeline systems supplies the capacity for constant monitoring. These sensing units can find modifications in pressure, temperature level, and vibrations, giving beneficial understandings right into the health and wellness of the welds over time.

Final Thought

To conclude, the assimilation of sophisticated strategies in pipeline welding inspection dramatically boosts the accuracy and dependability of weld assessments. Developments such as automated assessment systems, advanced imaging technologies, and non-destructive screening methods play a vital role in enhancing problem discovery rates and cultivating proactive upkeep methods. As these modern technologies remain to advance, they will better make certain the safety and security and effectiveness of pipeline systems, inevitably contributing browse around these guys to the integrity of critical framework.

Report this page